Monthly archives: May 2015

Entries found: 5

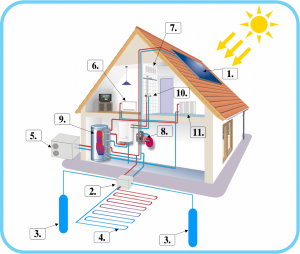

HEATING SYSTEMS FOR GREENHOUSES AND GLASS HOUSES

Maintaining the required temperature in the greenhouse or glasshouse is very important for the plants you wish to grow. The elements that you need to think about when choosing the right heating system is: installation cost and cost of maintenance and heating.

The heat pumps use heat energy from air or water and turn it into geo-thermal energy. For this heat energy transmission we use certain electric energy which is 3x less than the transferred.Using the heat pumps you save 75% of energy which is necessary to use during the heating of your greenhouses and glasshouses. The system is also capable of maintaining constant adjusted temperature in greenhouses and glasshouses which is necessary for yield of grown plants.

With FEMAN heat pumps you get a guaranteed highest possible field.

SOLAR COLLECTORS

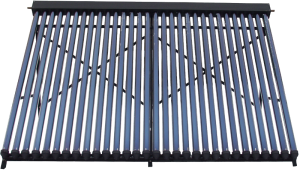

Pipe-like solar collectors compared to the flat square solar collectors have a coefficient of utilization of 75%.

Solar heating is a process of heating water through converted sun energy. The energy from the sun turns into heat energy with the help of sun receptors called solar collectors.

It is commonly known that the solar collector annually saves for 1m2- 589kWh energy. In the summer period it satisfies the needs for hot water 95-100% in the transition period 55-75% and in winter time 15-25%.

Solar collectors do not need any maintenance and they do not have any break-downs. The collector carriers are made of anodized aluminum. Vacuum pipes are made of tampered glass that give toughness and durability and the center of the pipe has a copper pipe.

Characteristics:

| Type | FSK30 |

| Dimension (length, width, height) | 2006x2456x182 mm |

| Weight | 102 KG |

| No. of vacuum pipes | 30 pcs, 1800 mm, ø58mm |

| Insulation thickness | 50 mm |

| Glass thickness of vacuum pipes | 1,8 mm |

| Material of vacuum pipes | Borosilicate glass |

| Absorption area | Al-N-SS/Cu |

| Max. operative temperature | 190 °C |

| Max. pressure (kPa) | 600 |

| Code | 4201000 |

FANCOILER WALL AND CEILING

Fan-coil equipment has the lamella surface condition for exchanging heat, on which with the help of fans the air flows in the room. Compared to the standard radiators, multiple increases the heat transmission thanks to the reinforced pipes shaped like common small ribs for heat exchange. Thanks to the large surface for heat exchange and to the fans that help the air flow, the unit is suitable for cooling rooms as well if the cold water is circulating through the system.

| Ceiling fan coiler : | Ceiling fan coiler : |

| FPFC 684P | FPFC 854P |

| Air flow 680m3/h | Air flow 850m3/h |

| Cooling capacity 3680W | Cooling capacity 4980W |

| Heating capacity 5480W | Heating capacity 7200W |

| Voltage: 220-240V/50Hz | Voltage: 220-240V/50Hz |

| Cover weight 2,5Kg | Cover weight 4,5Kg |

| Weight of internal unit 20Kg | Weight of internal unit 23Kg |

| Dimension: 590x590x270 | Dimension:752x752x293 |

| Code: 4200825 | Code: 4200830 |

| Wall fan coiler: | Wall fan coiler: |

| FZFC 400 | FZFC 600 |

| Air flow 680 m³/h | Air flow 1020 m³/h |

| Cooling capacity 3600 W | Cooling capacity 5400 W |

| Heating capacity 5400 W | Heating capacity 8100 W |

| Voltage: 220V/50Hz | Voltage: 220V/50Hz |

| Max working pressure 1.6 Mps |

Max working pressure 1.6 Mps |

| Weight 15 kg | Weight 18 kg |

| Dimension: 896x296x170 | Dimension: 1080x330x215 |

| Code: 4200815 | Code: 4200820 |

HEAT PUMPS AIR-WATER

Heat pump Air-Water takes energy from air and transmits it to water. Optimizing the parameters of the heat pump you achieve the maximum coefficient of economic effect throughout the year. The air is brought into the heat exchanger in which one part of the underground water in transmitted into the ecological Freon which evaporates. The Freon that is now in gas condition is pressed via compressor and releases latent transferred heat to the water that circulates through the condensers and heat systems in buildings.

Using the heat pump air-water you will save up to 75% of energy for heating homes, offices, greenhouses etc.

Also another advantage of this product is that you can cool the room during summer time. The heating system has the most utilization during the transition period. These systems can be used on the existing central heating systems such as wood, coal or gas.

To increase the capacity, connect more pumps in one system.

| Type | FTPVZ21 | FTPVZ36 | Characteristics: | ||

| Code | 4200322 | 4200336 | Dimension | 1115x430x1260 mm | 1450x750x1060 mm |

| Power consumption | 5,26 KWh | 9,8 KW | Noise | 60,0 db | 60,0 db |

| Heating Capacity | 21 KW | 36KW | Compressor | Coperland – USA | Coperland – USA |

| Saved energy | 15,74 KW | 26,2 KW | Body | Stainless steel or painted | Stainless steel or painted |

| Cooling Capacity | 16 KW | 29,4 KW | Working gas | R404 A/2,9kg | R404 A/2,5kg |

| Nominal power intensity | 10 A | 18A | Max gas pressure | 2,8 Mpa | 2,8 Mpa |

| Voltage | 380V/50Hz | 380V/50Hz | Min gas pressure | 0,08 Mpa | 0,08 Mpa |

| Temperature of output water | 55º | 55º | Water pressure drop | 0,01 – 0,02 Mpa | 0,01 – 0,02 Mpa |

| Weight | 142 kg | 310 kg | IP protection | x4 | x4 |

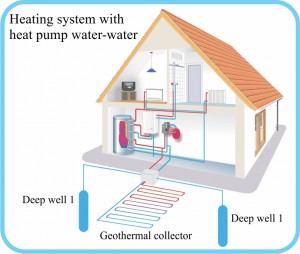

GEOTHERMAL SOURCE HEAT PUMPS WATER-WATER

The heat energy can be taken from the

underground waters that are on temperature of 14 °C throughout the whole year. From a drilled well the water is brought into the heat exchanger in which one part of the underground water is transmitted into the ecological Freon which evaporates.

For 1kWh of used electric energy in the output you receive total heat energy of 3-4 kWh. Energy gained in such process is called geo-thermal energy. In common practice heat pumps are mainly used for cooling space and as well for heating water.

Partially cooled water returns to the second well which is the same deepness as the first well so in that way the flows of the underground water are not disturbed. The Freon which is now into gas condition is pressed via compressor and releases latent transferred heat to the water that circulates through the condensers and heat systems in buildings.

Heat pump WATER-WATER is exploited as a device that uses accumulated heat from the ground and with the help of electricity turns into heat energy for heating or cooling system, depending on the need.

The system functions by setting polyethylene

pipes in ground under depth of 1.2 to 1.5m. The distance between the pipes should be from 0.5-0.8m. The width of the pipes is determined based on the project. The heat pump in this system uses the antifreeze as a intermediary for transferring the ground heat.

If it is not possible to set up the geothermal collectors due to lack of space or if you need a system with higher effect than we recommend geothermal probes. In this case you drill holes in the ground hundreds of meters deep and than insert polyethylene pipes.

With the heat pumps you achieve large utilization by setting up horizontal collectors beneath the livestock manure that in winter period accumulates the needed temperature.

To increase the capacity, connect more pumps in one system.

Heat pump WATER-WATER have the possibility to use the energy from water and earth. Heat pump WATER-WATER is used to heat or cool: homes, apartment units, office space, green houses etc. These systems can be installed on existing central heating units for example wood, coal or gas.

Heat pump water-water takes its energy from water and transmits it also into water in a different place. When, as heat source we use groundwater which has the same temperature of 14 to 16 °C throughout the whole year, optimizing the parameters of the heat pump you achieve the maximum coefficient of economic effect throughout the year.

The heat energy can be taken from the

underground waters that are on temperature of 14 °C throughout the whole year. From a drilled well the water is brought into the heat exchanger in which one part of the underground water is transmitted into the ecological Freon which evaporates.

For 1kWh of used electric energy in the output you receive total heat energy of 3-4 kWh. Energy gained in such process is called geo-thermal energy. In common practice heat pumps are mainly used for cooling space and as well for heating water.

Partially cooled water returns to the second well which is the same deepness as the first well so in that way the flows of the underground water are not disturbed. The Freon which is now into gas condition is pressed via compressor and releases latent transferred heat to the water that circulates through the condensers and heat systems in buildings.

Heat pump WATER-WATER is exploited as a device that uses accumulated heat from the ground and with the help of electricity turns into heat energy for heating or cooling system, depending on the need.

The system functions by setting polyethylene

pipes in ground under depth of 1.2 to 1.5m. The distance between the pipes should be from 0.5-0.8m. The width of the pipes is determined based on the project. The heat pump in this system uses the antifreeze as a intermediary for transferring the ground heat.

If it is not possible to set up the geothermal collectors due to lack of space or if you need a system with higher effect than we recommend geothermal sonds. In this case you drill holes in the ground hundreds of meters deep and than insert polyethylene pipes.

With the heat pumps you achieve large utilization by setting up horizontal collectors beneath the livestock manure that in winter period accumulates the needed temperature.

To increase the capacity, connect more pumps in one system.

| Type | FTPVD22 | FTPVD36 |

| Code | 4200222 | 4200236 |

| Power consumption | 5.26KW | 8.8KW |

| Capacity heating | 22KW | 36KW |

| Saved energy | 15.74 kW | 27.2 kW |

| Cooling capacity | 16 kW | 26.4 kW |

| Nominal power intensity | 10A | 18A |

| Voltage | 380V – 50Hz | 380V – 50Hz |

| Temperature of input water | 55oC | 55oC |

| Protection degree | IPX4 | IPX4 |

| Body | Stainless steel | Stainless steel |

| Compressor | Coperland USA | Coperland USA |

| Cooling gas | R404 A/2.9kg | R404 A/2.3kg |

| Water flow | 3700L/H | 6500L/H |

| Water pressure drop | 0.01-0.02 Mpa | 0.01-0.02 Mpa |

| Max pressure of re-set valve | 2.8 Mpa | 2.8 Mpa |

| Min. pressure of re-set valve | 0.08 Mpa | 0.08 Mpa |

| Dimension LxWxH | 710X710X710mm | 1060X780X740mm |

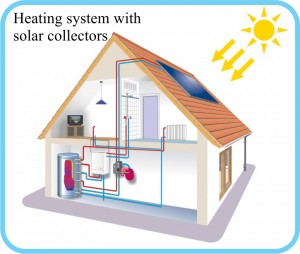

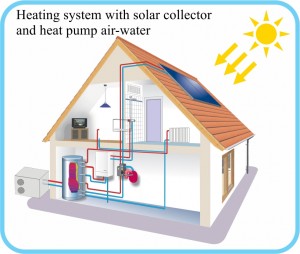

HEATING AND COOLING OF YOUR HOME-OFFICE SPACE WITH HEAT PUMPS AND SOLAR COLLECTORS ENERGY

Solar energy is the only inexhaustible source of warm energy.

In the period when there is not enough of sun energy, solar collectors are used in combination with heat pumps.

These types of systems are used for heating and cooling domestic homes, office space, swimming pools, green houses etc. The solar collectors combined with the heat pumps secure the biggest possible degree on energy saving and energy efficiency up to 75%.

Beside the big energy saving, these systems do not produce any harmful elements that endanger the environment such as wood fired cauldron, coal, gas, oil etc.

- Solar collectors

- Heat pump water-water

- Well 1 and well 2

- Horizontal geothermal collector

- Heat pump air-water

- Fan coiler mural

- Fan coiler – ceiling

- Pump

- Boiler

- Hot water

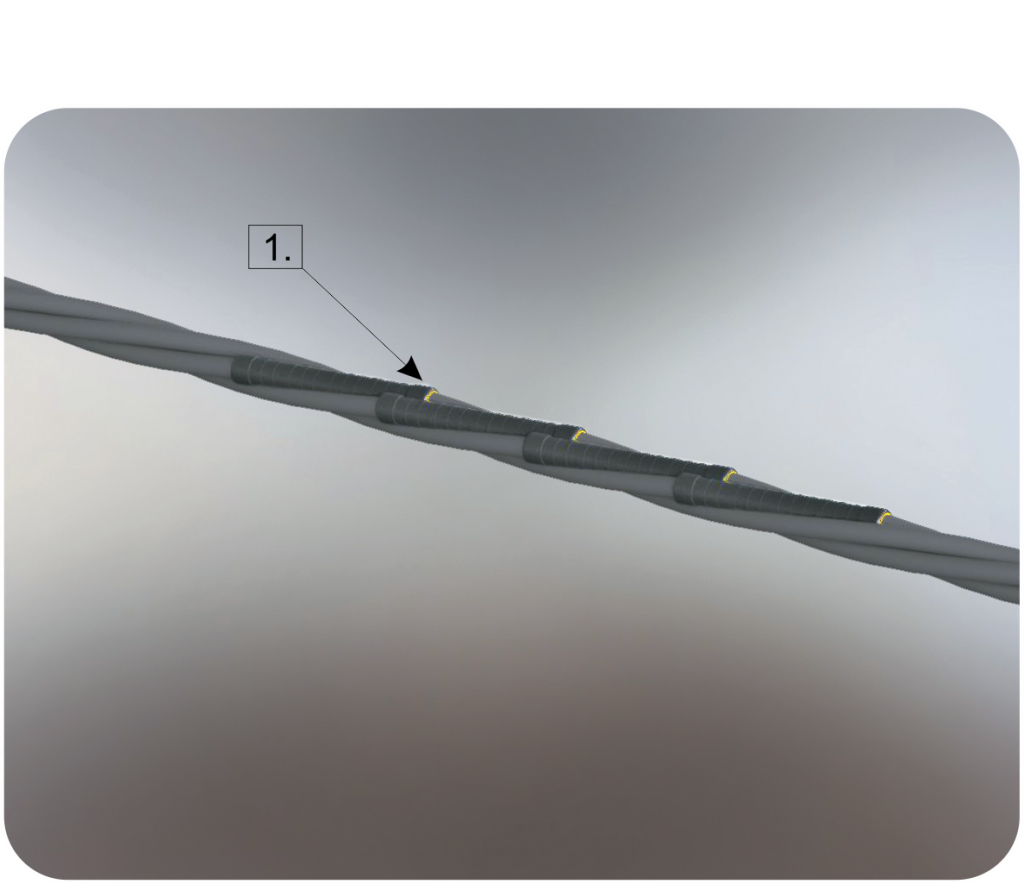

Installation example No.21

Connection of insulated conductors ABC in the range

Material list necessary for installation :

| No | Code Marking | Products Name | Note | Quantity | pcs. |

| 1 | 3417070 | MJPT 70N | FID-N jointing sleeves for conductors-zero conductor | 4 |

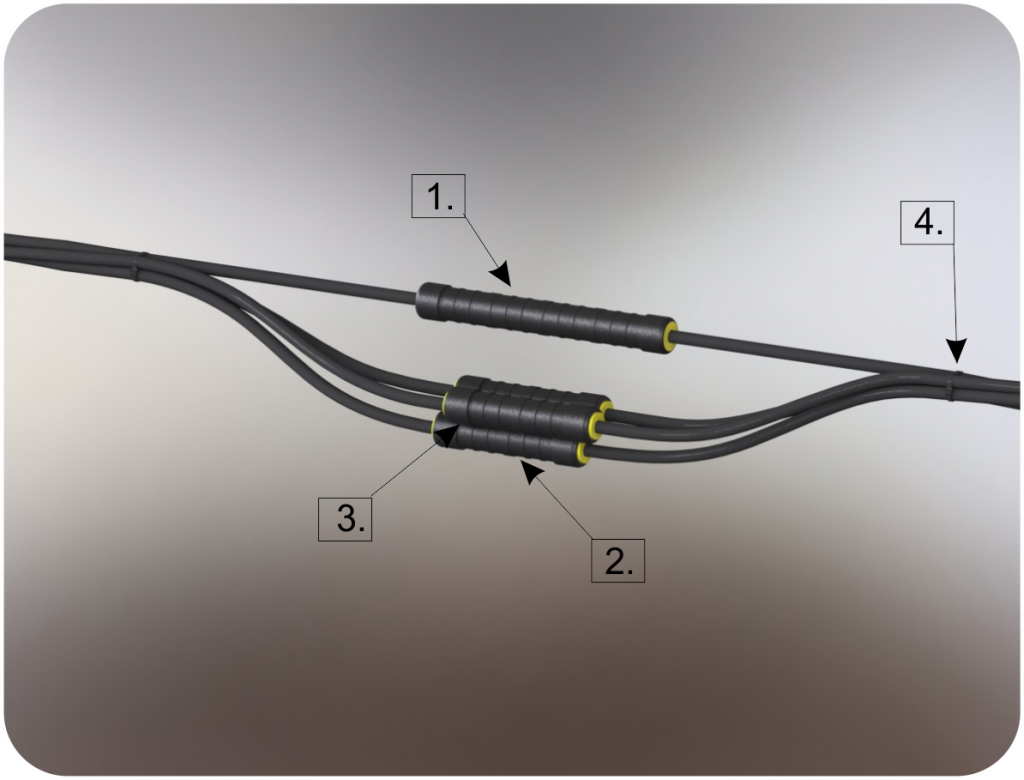

Installation example No.20

Connection of insulated conductors ABC in the range

Material list necessary for installation :

| No | Code Marking | Products Name | Note | Quantity | pcs. |

| 1 | 3415454 | MJPT 54 N | FID jointing sleeves for phase conductors | 1 | |

| 2 | 3402525 | MJPT 25 | FID jointing sleeves for phase conductors | 1 | |

| 3 | 3405050 | MJPT 50 | FID jointing sleeves for phase conductors | 3 | |

| 4 | 1710189 | FKV 180/9 | Cable tie | 2 |

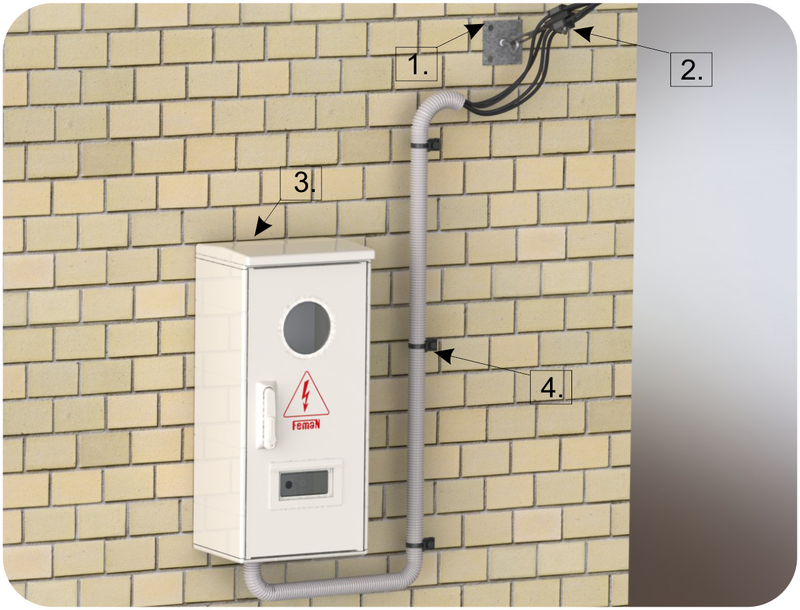

Installation example No.19

Connection on the building with entrance through the measuring-distribution enclosure- electric meter

Material list necessary for installation :

| No | Code Marking | Products Name | Note | Quantity | pcs. |

| 1 | 3810008 | AC 25 | Steel wall bracket for household connection of ABC | 1 | |

| 2 | 3813025 | PA/PS 416/35 | Tension support clamp for LV ABC | 2 | |

| 3 | 5082030 | MRO 1 | Measuring-distribution polyester enclosure 320x665x235 | 1 | |

| 4 | 1714060 | FZN 60 | Wall bearer with binding thread | Distance gap between vulture and the wail of the building must be at least 0.06M | 3 |

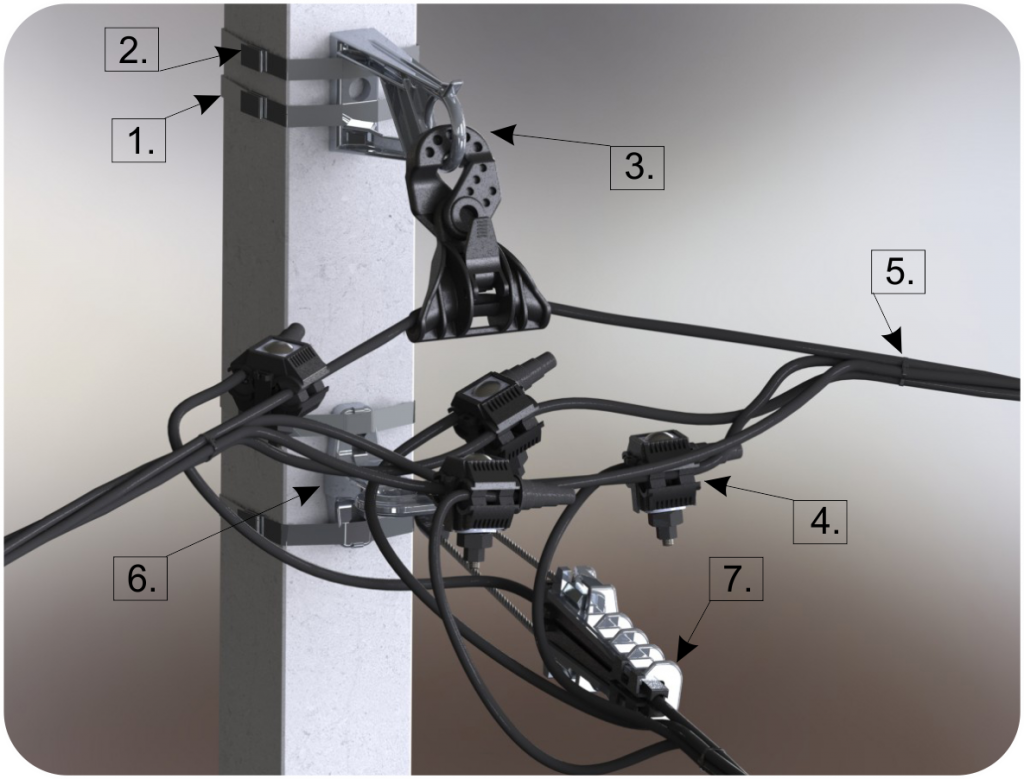

Installation example No.18

Angular carrying support of the main ABC line and separating for household connection

Material list necessary for installation :

| No | Code Marking | Products Name | Note | Quantity | pcs. |

| 1 | 4710080 | F 207 | Stainless steel band | (0.19×0.7x5000M) | 4 meters |

| 2 | 4710320 | A 20 | Clips | 19 mm | 4 |

| 3 | 3810021 | ES 1500 | Al bracket with clamp for carrying support up to 25-95mm² conductor | 1 | |

| 4 | 3804350 | PC 4-150 | Insulated waterproof connecting clamp FIDOS 4-35/6-150 | 2 | |

| 5 | 1710189 | FKV 180/9 | Cable tie | 3 | |

| 6 | 3810013 | CA 1500/2000 | Al bracket | 1 | |

| 7 | 3811625 | PA 25 | Tension support clamp for household connection | 1 |